Top-Quality Services

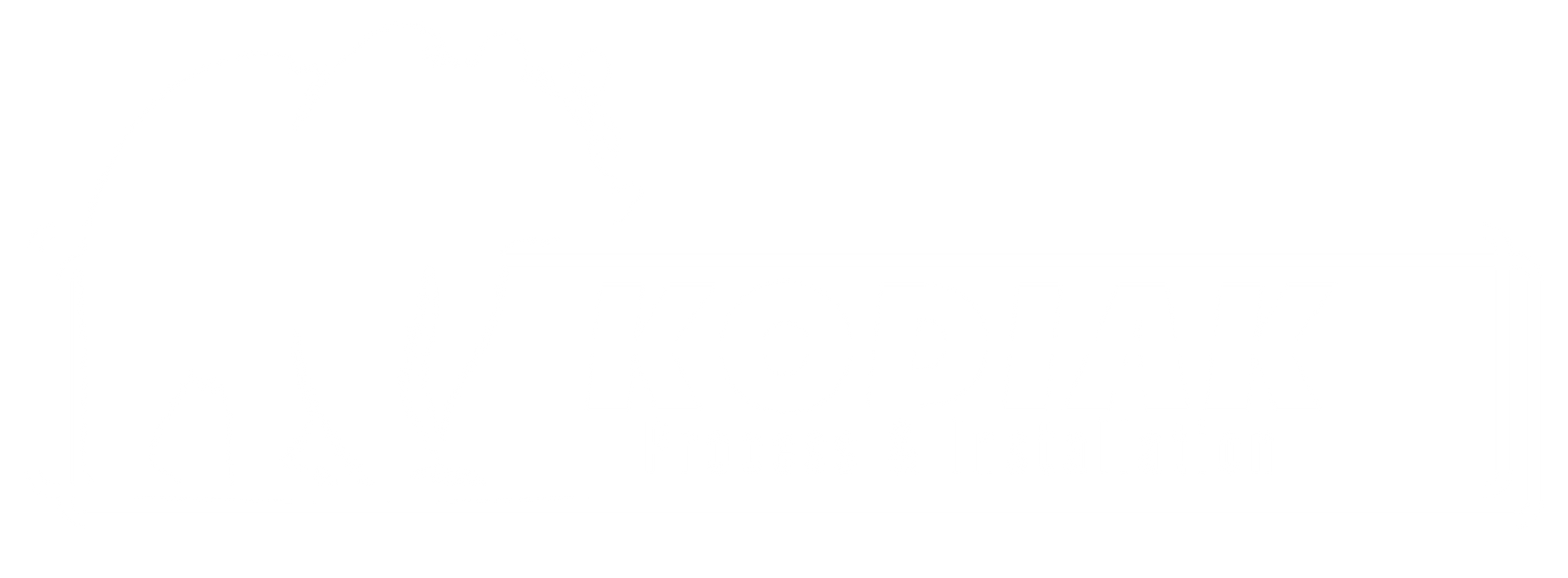

PROCESS PIPING

- Custom Fabrication & Installation – Designed to meet industry-specific requirements.

- Sanitary & High-Purity Piping – Precision welding for food, dairy, and pharmaceutical applications.

- Stainless Steel & Specialty Alloys – High-quality materials for durability and compliance.

- System Repairs & Modifications – Minimize downtime with expert repairs and upgrades.

- Turnkey Solutions – From design and fabrication to installation and testing.

- Regulatory Compliance – Meeting 3A, FDA, and other industry standards.

- Efficient & Reliable Performance – Engineered for optimal flow and longevity.

- Experienced & Certified Welders – Skilled professionals ensuring top-tier craftsmanship.

UTILITY PIPING

- Custom Design & Installation – Tailored solutions for steam, water, air, and gas systems.

- High-Quality Materials – Stainless steel, carbon steel, copper, and other durable options.

- Process Efficiency – Optimized layouts to improve performance and reduce energy costs.

- System Repairs & Upgrades – Minimize downtime with expert maintenance and modifications.

- Compliance & Safety Standards – Meeting OSHA, ASME, and industry-specific regulations.

- Steam & Condensate Systems – Engineered for maximum efficiency and reliability.

- Compressed Air & Gas Piping – Designed for safe, efficient delivery of critical utilities.

- Cooling & Heating Systems – Reliable solutions for temperature control in industrial settings.

- Certified & Experienced Team – Skilled professionals ensuring top-tier workmanship.

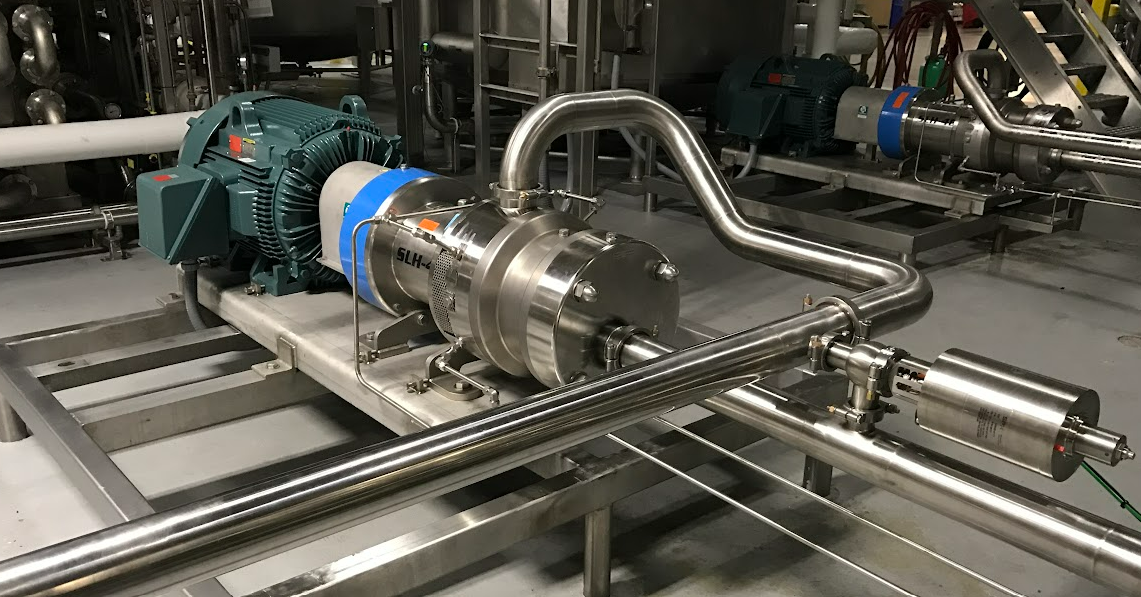

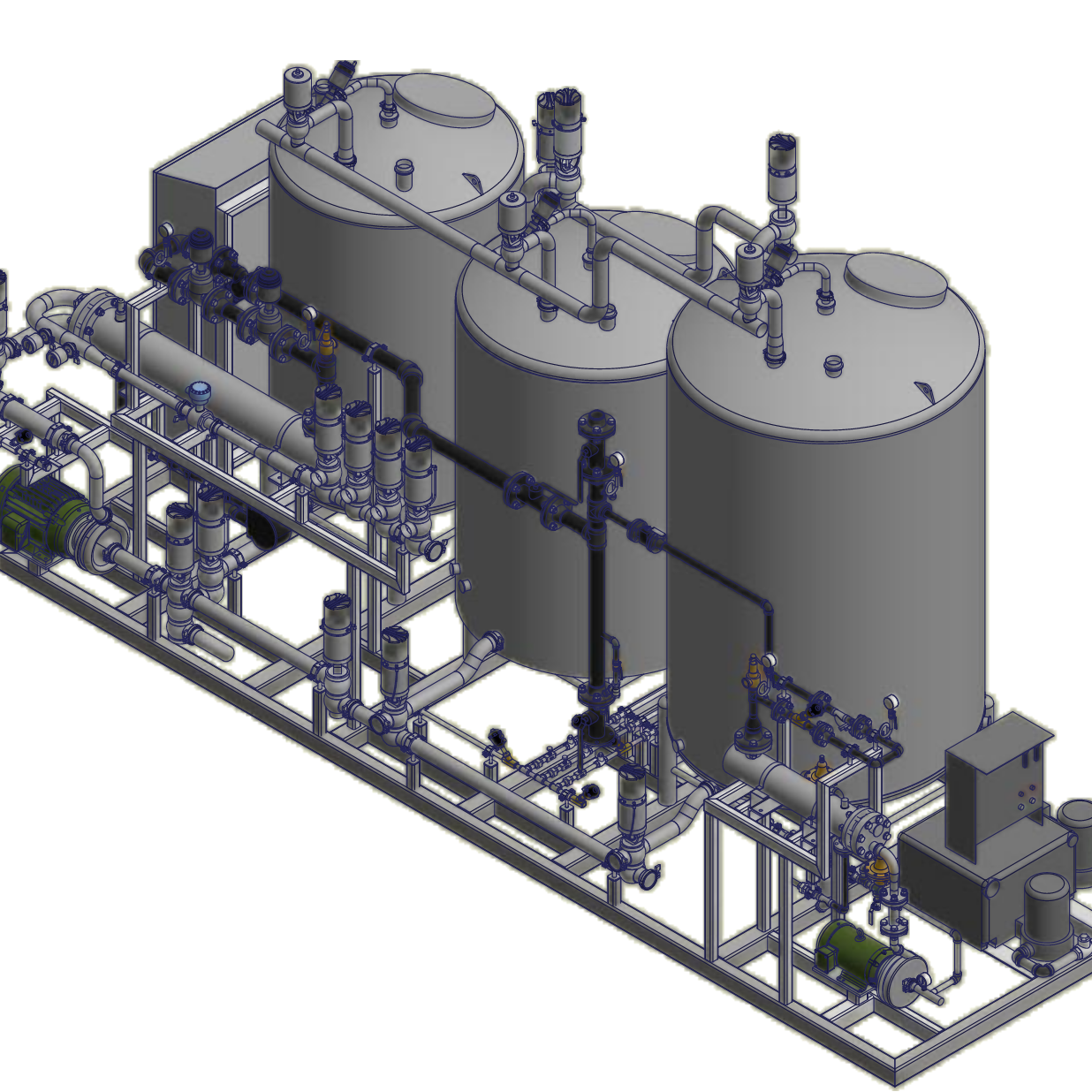

SHOP FABRICATION

- Custom Fabrication – Precision-crafted components tailored to your specifications.

- Sanitary & Process Piping – High-quality welding for food, dairy, and pharmaceutical industries.

- Structural & Equipment Supports – Custom-built platforms, frames, and brackets.

- Stainless Steel & Specialty Alloys – Fabrication using durable, industry-approved materials.

- Quality Control & Testing – Ensuring compliance with industry standards before installation.

- Pre-Fabrication for Onsite Installation – Reducing downtime and improving efficiency.

- Experienced Craftsmanship – Skilled professionals delivering precision and reliability.

EQUIPMENT SETTING

- Precision Installation – Expert placement and alignment for optimal performance.

- Turnkey Solutions – From rigging and positioning to final connections and testing.

- Heavy Machinery & Process Equipment – Handling everything from pumps to full production lines.

- Leveling & Alignment – Ensuring accuracy for efficient operation and longevity.

- Utility & Process Piping Integration – Seamless connections for a complete system setup.

- Safety-Focused Execution – Meeting OSHA and industry-specific safety standards.

- Minimized Downtime – Efficient scheduling and execution to keep operations running.

- Equipment Relocation & Reconfiguration – Expert handling of plant moves and system upgrades.

- Experienced & Certified Team – Skilled professionals ensuring reliable, high-quality work.

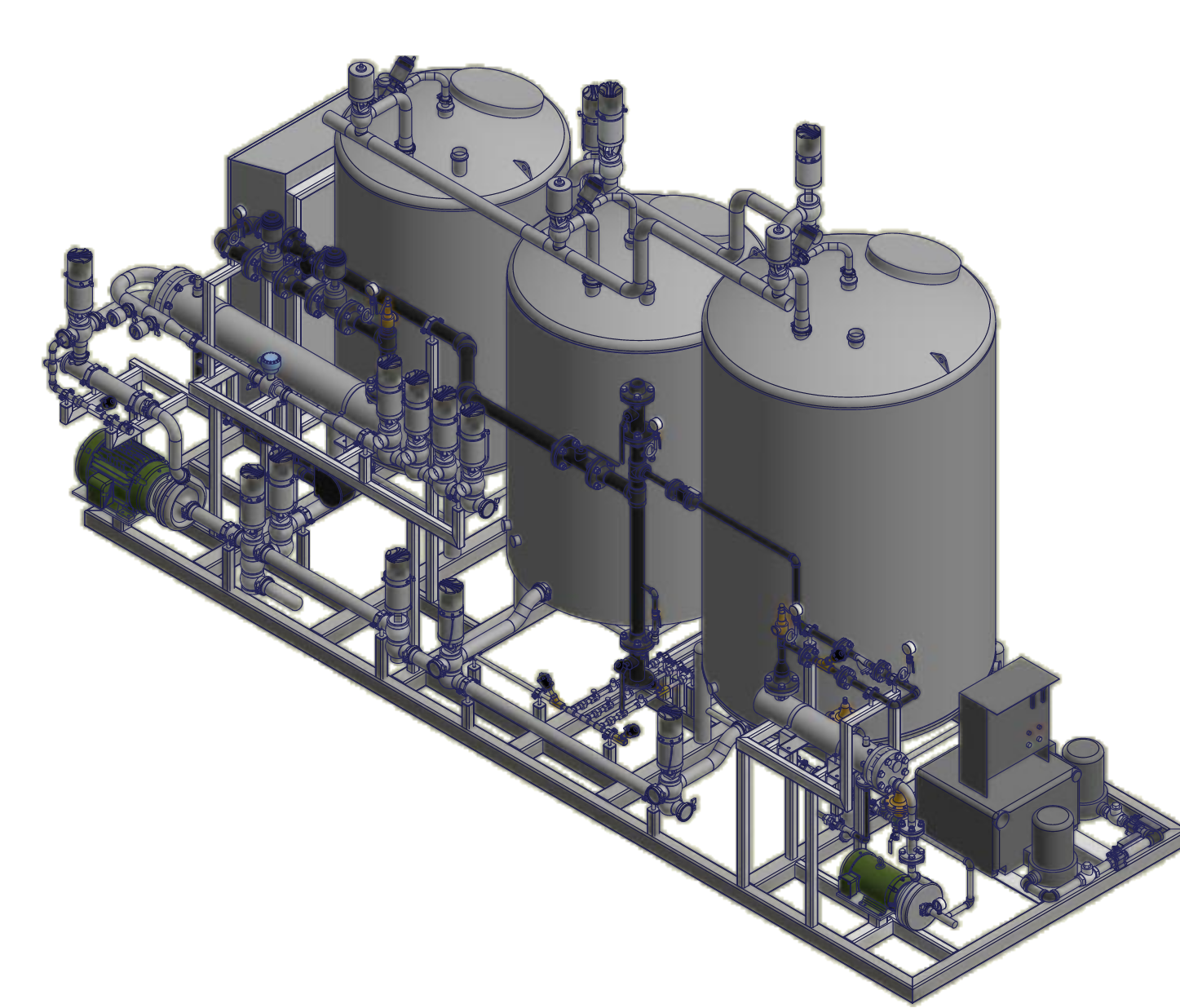

PROCESS ENGINEERING

- Custom System Design – Tailored solutions to fit your production needs.

- Process Optimization – Let us increase your productivity while reducing waste and costs.

- Regulatory Compliance – Ensuring adherence to FDA, 3A, CFR and other industry standards.

- Equipment & System Integration – Seamless coordination of process components.

- Automation & Control Systems – Let us automate your system to reduce downtime and overhead.

- Troubleshooting & Performance Analysis – Diagnosing issues and improving system reliability.

- Experienced Engineering Team – Delivering innovative, high-quality solutions in the food and beverage industry.

PROJECT MANAGEMENT

- End-to-End Oversight – Managing projects from planning to completion.

- Budget & Cost Control – Ensuring projects stay on track financially with experienced change order management.

- Scheduling & Timeline Management – Keeping projects on time and minimizing downtime.

- Quality Assurance – Upholding the highest standards in fabrication and installation.

- Resource Allocation – Efficient use of manpower, materials, and equipment.

- Clear Communication – Coordinating with clients, vendors, and teams for smooth execution.

- Problem-Solving & Adaptability – Quick resolution of issues to keep projects moving forward.

- Experienced Leadership – Skilled professionals ensuring successful project delivery.